Home

About Us

WE ARE ASO BRICK FACTORY

Established in 2005, Aso Brick Factory stands as one of the most remarkable ventures of the Halabja Group, encompassing an expansive area of 210,000 square meters. With a primary focus on producing red bricks adhering to world-class standards and epitomizing the highest quality, the factory plays a crucial role in meeting the domestic demand for this essential construction material.

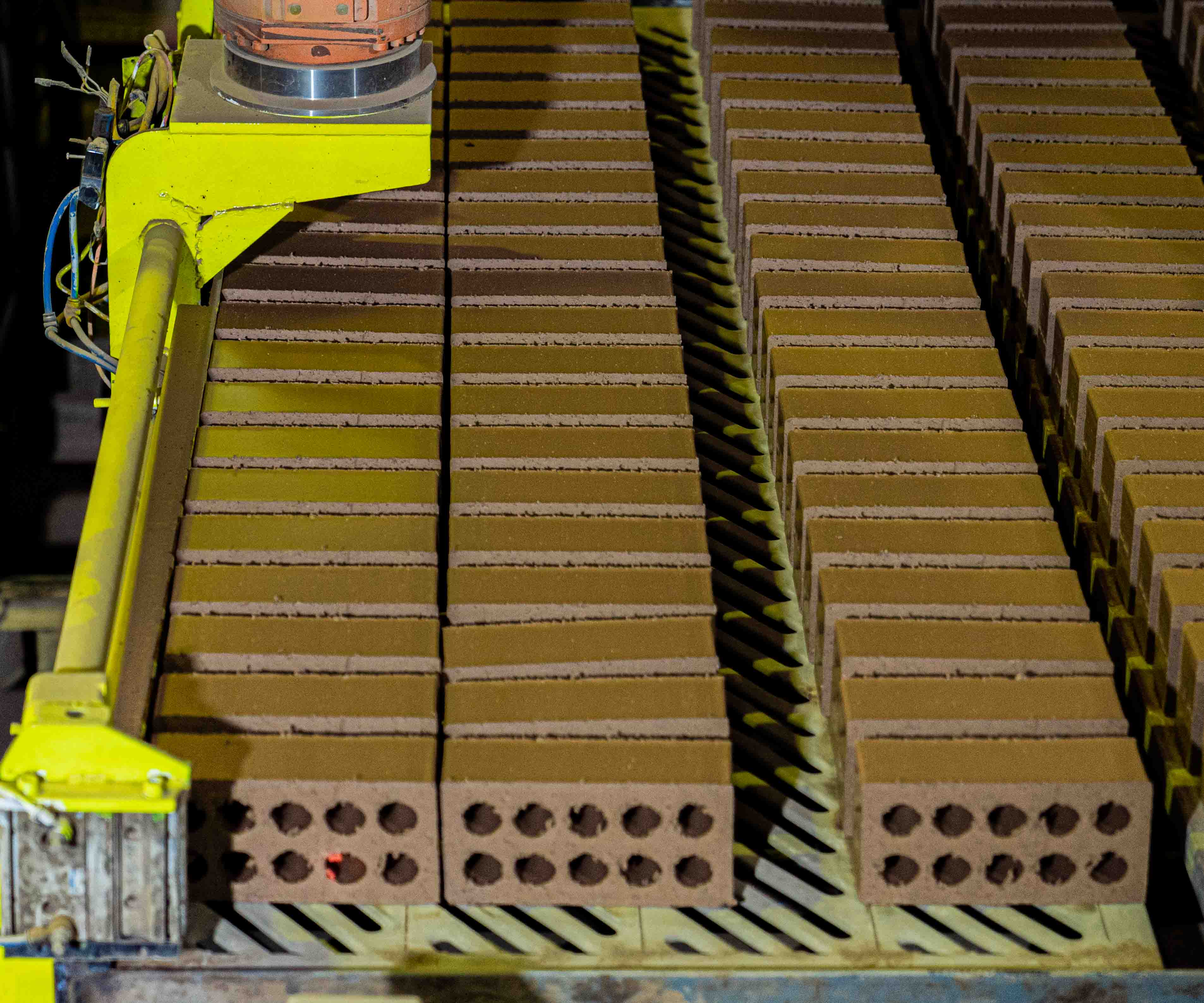

From its inception, Aso Brick Factory has remained committed to innovation and the incorporation of cutting-edge technology in brick production, earning the factory a distinguished reputation within the construction markets of the Kurdistan Region and Iraq.

The factory's exceptional product quality and diverse range have garnered considerable attention from investors and project owners, who now prefer Aso Brick's offerings for their ventures, ensuring seamless deliveries to their customers. Consequently, the utilization rate of the factory's products has experienced a notable annual surge as more individuals opt for them in their construction endeavors.

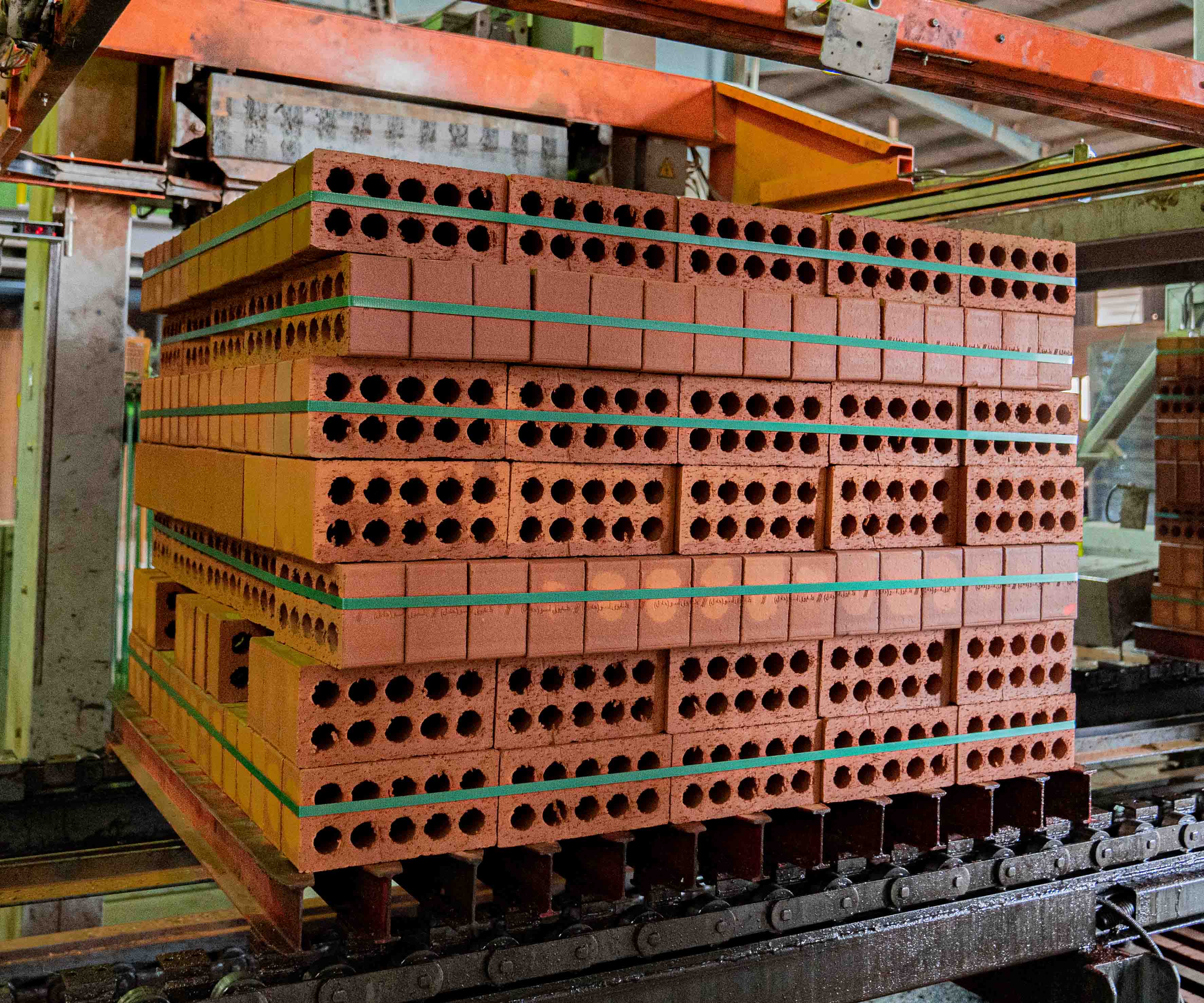

With a daily production capacity of 1250 tons of bricks, Aso Brick Factory has contributed significantly to the local economy by creating over 200 job opportunities in the region.

Moreover, the factory takes proactive measures to protect the environment, exemplified through the implementation of sewage recycling systems, carbon waste reduction, and consistent greening initiatives within the factory's premises. Such sustainable practices underscore the factory's commitment to ecological responsibility and environmental preservation.

Aso Brick Factory engages in the production of a diverse range of 11 brick types, comprising 6 variants of Load-bearing brick and 5 types of non-load-bearing (Partition) brick.

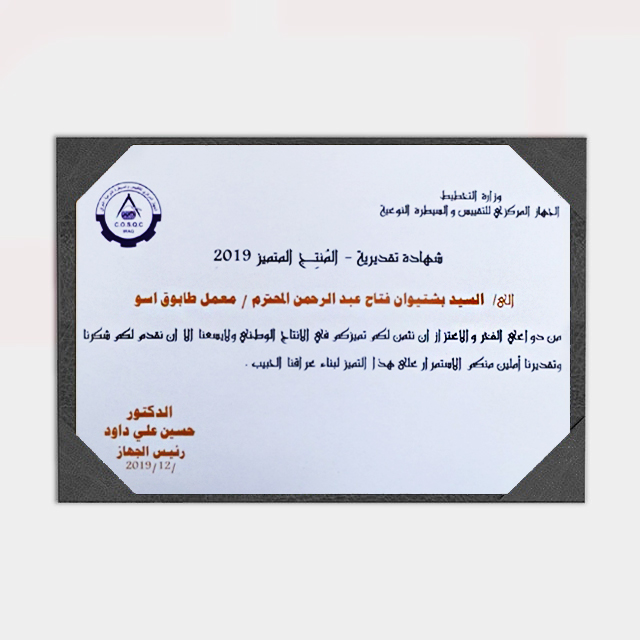

Also, the factory consistently meets the highest quality standards, as recognized by various domestic and international awards and certificates one of which is the selection of the best construction materials factory for 2019 by the Measurement and Quality Control Board of the Iraqi Ministry of Planning.

OUR PRODUCTION PROCESS

AWARDS

Aso Brick Factory consistently meets the highest quality standards, as recognized by various domestic and international awards and certificates

Having Enquiries?

Contact us at anytime, and we will address your questions.

Feel free to reach out to us for any questions, concerns, or inquiries you may have. Our dedicated team is here to assist you promptly and provide personalized support.

A subsidery of Halabja Group of Companies